When Colin Haines's boat won't start, he begins troubleshooting and ends up replacing his failed starter motor

Before moving my 28ft yacht from her marina berth to the travel hoist, I pressed the engine’s starter button, and instead of the engine starting, I heard ‘errrr, errrr, errr’ followed by silence.

Further attempts only resulted in the sound of a single click and no attempt to start the engine rotating.

Now what? It couldn’t be a flat battery, could it? I’d unplugged the shore power immediately before trying to start the engine, but batteries can fail suddenly.

It was summer, so the battery wasn’t too cold to work. Lead acid batteries have several vertical lead plates inside the black plastic box, each coated with various types of lead sulphate and other elements.

To aid the adherence, the plates can have a waffle-like surface.

Sometimes the sulphate can change into lead sulphide, which is counterproductive, but worse can happen when the material on the plates, which is a bit like wet clay, falls off the plates.

One effect is to reduce the battery’s capacity to hold a full charge as the material forms an electrically conductive sludge in the bottom of the battery.

As soon as the sludge builds up high enough to reach the bottom of one or more of the plates, the battery won’t hold a charge.

Instead, it just gets warm due to the electrical resistance of the sludge, and the battery charger lies when its amp meter claims to be charging the battery.

Lead sulphide can form in lead-acid batteries, which can reduce the charge the battery can hold

Most boats have some type of display to show what the voltage is in the domestic lighting batteries.

Few have anything to show the far more important charge state of the engine’s starter battery, especially when there’s no manual means of starting the engine.

It was a deficiency I’d already made good by installing a Lascar EMV 1200 voltmeter on the boat’s switch panel.

It’s powered by the starter battery. I didn’t need to get out a multimeter to see that there were only 12.4V available in the starter battery.

It returned to 12.7V later after recovering from trying to start the engine.

Many years ago, I’d applied my mind to the question of a flat engine battery when anchored in some remote place and made something ready to use if the starter battery suddenly failed.

Taking as my guide the size of the wires connected to the starter motor, I created a link between the domestic batteries and the starter battery, using a normal 400A isolation switch sold by most chandlers to separate the two systems.

Feeling pleased with being able to insert the switch’s key and immediately connect the 340Ah domestic batteries to solve the problem, I returned to the cockpit.

Parts of the starter motor

Pressing the starter button produced a click and nothing more. Oh!… Now what?

After checking the cables were all well attached – they were – it left me wondering if the starter motor’s little gear wheel that engages with the gear teeth on the flywheel had somehow jammed the engine.

It was a frequent enough problem years ago for it to be common knowledge that the ‘cure’ was to roll the car forwards, and then lift the clutch with reverse gear engaged.

Boats, of course, can’t be bump-started, so that wasn’t an option,

The easy way to check if the small gear was jammed against the flywheel was to apply a spanner to the head of the bolt holding the drive belt’s pulley wheel onto the end of the crankshaft.

My Volvo Penta 2002 engine rotates the pulley wheel clockwise, meaning that I wouldn’t be trying to undo the bolt.

There was little risk because the engine turned easily enough. But I still heard nothing more than a click when I tried to start the engine.

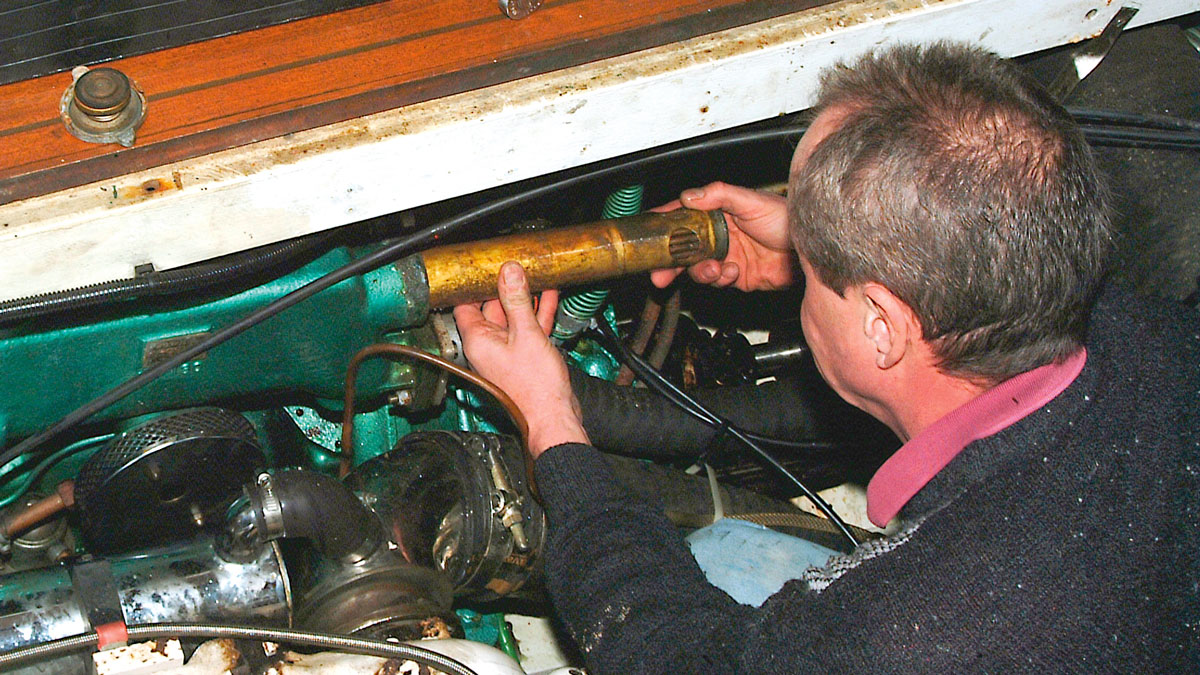

To remove the starter motor, the cap screws need to be removed, but first, you have to locate them; not so easy, given their position (yellow arrow). Credit: Colin Haines

It’s not a good idea to have the starter motor spinning all the time that the engine is running.

Very old cars used to have a ‘Dynostart’ where the engine spun the starter motor and became a dynamo that generated power for spark plugs and lights.

The world has moved on and now starter motors only spin when powered by an activating solenoid – it looks like a small cylinder on top of the motor.

It’s a cylinder because inside is a component like a cotton reel, with copper wire wrapped around it.

Pressing the starter button connects the battery to this coil of wire, turning it into a magnet.

The magnetic field inside the solenoid tries to pull an iron rod into it (shaded red in the diagram).

A lever (shaded blue) attached to the rod pushes a small gear wheel out to where its teeth engage with the teeth that go all the way around the flywheel.

The other end of the rod connects the battery to the motor.

This is where the wires are connected to the rear of the starter motor’s solenoid. Credit: Colin Haines

There is an audible click as this mechanism operates, as it usually will even if there is not enough power in a battery to turn the engine.

Identifying a starter motor is easy. Finding it may not be so easy because engine manufacturers cover everything with paint.

In the case of my Volvo, the engine is spray-painted green making it hard to identify which wires are connected to what.

The starter looks like a horizontal cylinder with a smaller one on top and is always located beside the engine at the gearbox end.

The body of my starter motor was more than pleasantly warm to the touch suggesting that the motor windings had failed somehow.

When power is delivered to any electric motor, it is almost a dead short for a fraction of a second before it begins to spin.

As soon as it does, it becomes a form of generator pushing power back to the battery and eliminating the dead short – hence the old ‘Dynostart’ – and the same happens with a starter motor that generates a back-flow eliminating the short circuit effect.

Mending the motor would be possible if the graphite brushes were worn out, but clearly, mine were OK because power was reaching at least one of the armature’s hot static coils.

Electricity flowing through the coils makes them generate a magnetic field that pushes against the magnetic fields of magnets fixed inside the motor case, making the motor start to turn.

The new, black, starter motor installed with attached silver solenoid. The original was camouflaged in Volvo green paint. Credit: Colin Haines

In so doing, the brushes contact a different part of the armature disc and the power is delivered to a different set of coils whose magnetic field then pushes against the fixed magnets.

And so it goes on, continually energising different coils.

If one coil has ‘burnt out’, meaning the copper wire, or more likely the insulating varnish coating that separates the copper wires has failed due to overheating, then the motor won’t turn. Instead, it gets hot.

Repair is uneconomical.

The internet was filled with vendors selling starter motors for my engine. It pays to be wary of the amount of power a battery can deliver if the two terminals are connected without a ‘load’ between them.

Decades ago, the screwdriver I accidentally dropped onto my car’s battery produced a brilliant spark that immediately melted the steel shaft. Hence disconnecting both cables from the engine’s battery before doing anything.

The starter is attached to the side of the engine with two M12 socket head cap screws.

However, the standard M12 Allen key in the boat’s collection of tools would not fit down into the available space, and the hard metal had to be shortened with an angle grinder to get into the space available.

Once I’d done that, removing the screws was easy enough, although space was tight.

Installing the new starter motor was easy, it simply needed to be held in place as the mounting screws were inserted. (The word ‘easy’ ignores the physical contortions needed to get both hands into the space and how they hid what I was doing.) I didn’t paint the motor’s black body green and hide the ID plate, the lack of which had given me so much trouble identifying what I needed to buy.

The lack of access also meant I couldn’t see the two spade terminals at the end of the new starter.

The original motor only had one small terminal plus a big one for the cable from the battery and cable from the alternator which is secured by a nut.

Having groped for, and found what felt like the right place to attach the wire from the cockpit control panel, I chose the wrong terminal.

I was not impressed when I pressed the starter button and nothing happened. I phoned the supplier, The Starter Motor & Alternator Company.

The knowledgeable voice at the other end of the phone told me what I’d done wrong.

After attaching the wire to the correct spade terminal, the engine started with the press of the button.

Back home Yorkshire thrift motivated me to dismantle the defective motor to see if I could repair it.

The 30-year-old brushes could have been new, so little was the wear.

After detaching the gearbox, and seeing what could be brand-new gears that turned freely, I looked inside the motor casing to find out why I could not turn the armature.

The reason was obvious.

Part of one of the permanent magnets had lost interest in being bonded to the motor case’s inferior, and, as the armature had started to rotate, the errant magnet had become jammed into the armature.

The ‘errr, errr, errr’ noise had been the sound of the armature trying to destroy the magnet.

Starter motors are reliable, so reliable that Volvo Penta saw no need to make any provision for hand starting the engine.

What I would have done had my boat been anchored in a remote Essex creek, rather than moored in a marina, does not make for comfortable contemplation.

I’ve now got the modified Allen key on board, and for £90, can carry a spare starter motor.

It took decades for the first starter to fail, and I’ve no reason to expect the replacement to fail.

But, since installing it, I’m worried each time I press the starter button.

I’m now questioning if I should add a spare starter motor to my onboard collection of filters and drive belts.

Installing it while at anchor, or even when sailing out at sea would not be difficult.

It makes me wonder how many other boat owners assume that their starter motors will never fail when they are far away from any easy replacement.

Or if they carry any special tools needed to fit a new one.

How to service a marine diesel engine in 12 simple steps

It was time to service the marine diesel engine on our Maxi 84 cruiser. Knowing how to diagnose and fix…

How to service a marine engine cooling system

Is your boat's engine beginning to run hotter than normal? It may be time to service the cooling system, suggests…

Fixing and avoiding marine engine leaks

There is no need to put up with a leaky, smelly inboard engine. By dealing with small leaks as they…

Fixing boat engine cooling system problems

Stu Davies solves niggly Volvo Penta 2030 engine cooling problems

Want to read more practical articles like How to replace a failed starter motor on a boat?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter