Gilbert Park and Larry Rumbol explain why regular a regular oil test can increase the life and reliability of your boat engine – and save you money

Many, apparently healthy, people have routine health checks to pick up problems early and treat any issues before they cause significant, irreversible conditions.

One of the first tests done in a routine health screening is a blood test as this is an indicator of anomalies in other critical areas.

A laboratory oil analysis is like a blood test for your boat.

It will indicate if the engine has a problem with bearings, pistons, cooling system, cylinder liners, crankshafts, fuel system and much more.

Some sailors claim that rubbing the oil between your thumb and forefinger will tell if the oil has any life left in it.

The cable tie stops the tube from going too deeply into the engine. Credit: Gilbert Park

But this is foreshore folklore, it’s like rolling a drop of blood between your fingers and saying yes it clots, so it’s OK.

It is true that if the oil on the dipstick looks cloudy, water is present in the oil, but by then damage will have occurred many hours before this emulsion forms.

It may not manifest itself immediately but for sure irreversible accelerated wear has occurred and there will be consequences.

These may be as mild as the engine wearing out a few years early or equally as serious as bearing failure when called to work hard in bad weather, just when you need it.

An oil analysis will, of course, give you a considerable amount of other useful information.

Make sure the lab you use supplies readable, useful information, not just data.

There should be conclusions, recommendations, and a tech support person able and willing to talk to you in layman’s terms.

What happens during an oil test

When a sample of oil arrives at a laboratory, one of the first tests is the flash point test.

This measures the temperature at which the oil produces a vapour that can be ignited.

If the oil is contaminated with diesel (for example from a fuel injector issue) then the flashpoint is lower. This can be dangerous if too low.

A professional laboratory will put a sample through an Inductively Coupled Plasma Spectrometer which can detect in minute amounts (less than 10 microns) wear metals and other elements.

To obtain a sample of oil for a laboratory oil test, you’ll need a device to ‘suck up’ the oil, ideally one that fits the sample tube for the oil lab you choose – they do come in different sizes for different labs. Some labs provide a 50ml syringe instead. Credit: Gilbert Park

There are established limits which, when exceeded, create alerts at specific levels of severity.

The lab report will come to conclusions when subsequent monitoring or preventative maintenance has been carried out.

Knowing what is expected is the key and knowing it early is everything as intervention can reverse or prevent what insurance companies call a ‘catastrophic issue’ (irreversible critical damage).

If all the levels are within the normal range the lab report will be ‘green’ and say so.

When they are outside of the normal range then experience in their interpretation is needed.

Continues below…

No mess oil filter change for a boat engine

Simon Westmacott devises a way to keep his bilges clean when changing the engine's oil filter

Fixing and avoiding marine engine leaks

There is no need to put up with a leaky, smelly inboard engine. By dealing with small leaks as they…

How to service a marine diesel engine in 12 simple steps

It was time to service the marine diesel engine on our Maxi 84 cruiser. Knowing how to diagnose and fix…

How to fix a leak in the marine engine cooling system

Stu Davies advises PBO reader Richard Jales how to solve a leak in his boat's marine engine cooling system

The oil will also be tested for its Total Base Number (TBN). This measures the ability of the oil’s detergent additive to neutralise damaging acids from combustion.

There is a common belief that oil should be changed before laying the boat up for the winter.

Most pleasure boat engines are only used for 50-100 hours a year.

In normal usage this is insufficient to lower the TBN, thus the winter oil change is a waste of money.

However, a lab analysis when you lay up and one when you reactivate can prevent a great deal of woe.

The lab reports will be trended and interpretations made about changes and, of course, identify whether the oil is fit to use or has been contaminated over the winter.

Saving money

Oil analysis saves money by identifying wear or contamination early and avoiding unnecessary oil changes; it also reduces environmental impact.

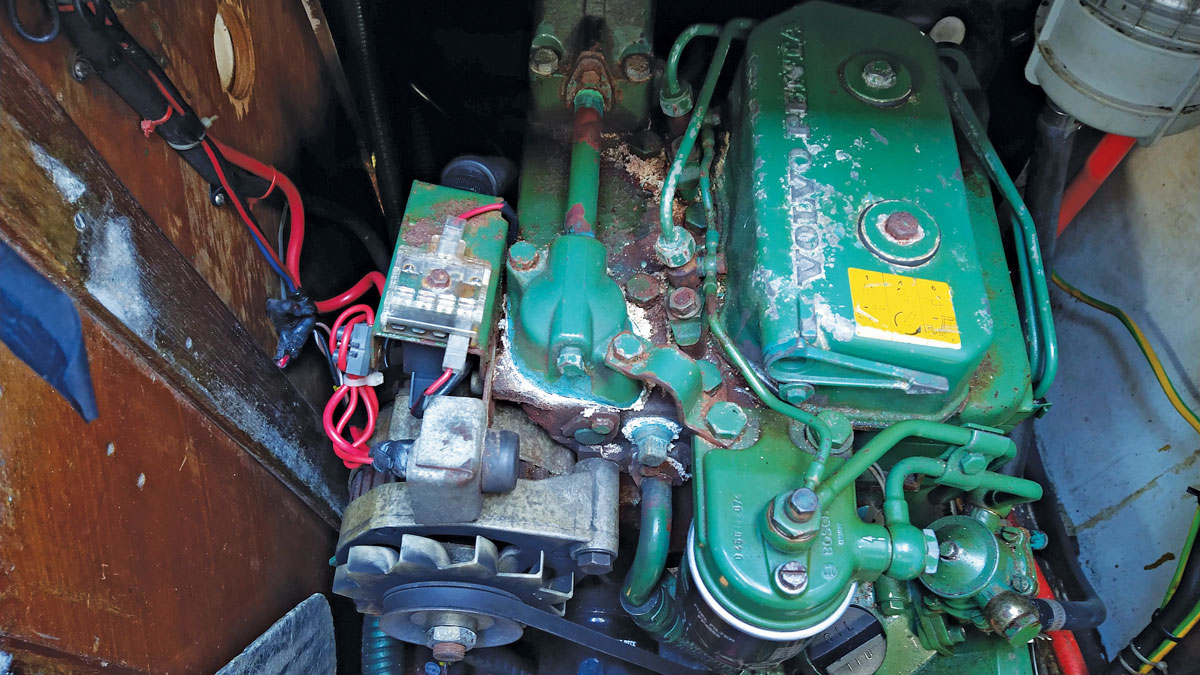

We asked Volvo Penta (which does its own oil analysis), Yanmar, Cummings, MAN, and Caterpillar to comment on oil analysis.

In particular, we wanted to know if the warranty of a new engine would be invalidated if the oil was not changed at intervals specified in the warranty documents, even if repeated oil analyses results showed the oil was performing satisfactorily and didn’t need changing.

You can avoid unnecessary oil changes by getting your oil tested

Unfortunately, no reply was received apart from one from Volvo Penta which said: ‘When you undertake an oil analysis, any repair time is reduced thanks to a clear understanding of the problem in advance. In this way, you can avoid unplanned downtime. At the same time, you maintain cost efficiency and consume less energy. Besides, an oil analysis result is valuable as it confirms your engine’s condition and raises its second-hand value. For some Volvo Penta engines, regular use of oil analysis could lead to extended service intervals to maximise the life of your engines.’

It can be said, perhaps cynically, that an independent laboratory analysis does avoid manufacturers ‘marking their own homework’.

Taking a sample for an oil test

It is important to note that a single oil analysis, while valuable, is even more valuable when the testing is done regularly showing trends.

Regular oil analysis may also increase the resale value of the boat and is something diligent surveyors should always do when conducting a sale/purchase survey.

An engine repair nearly always represents a significant percentage of the cost of a boat.

In each oil test pack, you’ll find tubing, a plastic bottle, an information sheet and a return label. Credit: Gilbert Park

Kits are available from chandlers Force 4 under an arrangement with the independent UK laboratory group Spectro | Jet-Care.

These include a sample bottle, tubing, a mailing container, and documentation.

Force 4 also sells a vacuum pump that fits the bottle ensuring vital zero sample contamination and mess.

Other labs supply a 50ml syringe to suck up the oil.

The Force 4 option, costing around £65, is also postage paid so just needs posting; the results will be available two working days after the sample has been received.

Taking an oil sample for analysis is very straightforward.

The tube should not go down to the bottom of the sump which contains sludge and will distort the results. To prevent this, measure the length of tube from near the lower oil limit on the dipstick to the dipstick stopper. Credit: Gilbert Park

The engine must be at its running temperature and the oil sample taken quickly so that all the particulate material is still suspended in the oil. Preparation is essential.

The tubing should not go down to the bottom of the sump, as there is sometimes sludge present that can invalidate the measurements and block the tube.

This can be avoided by pushing the tube down the tubing for the dipstick until it hits the bottom and then pulling it back a couple of centimetres.

The extraction tube slides into the dipstick tube, the depth marked with a cable tie. Credit: Gilbert Park

Alternatively, place the end on the lowest dipstick mark and measure upwards to where the dipstick seals at the top, and secure a cable tie at that point.

Attach the tubing to the suction device and insert the tubing down the dipstick pipe until the cable tie is at the entrance to the dipstick pipe.

Slowly aspirate the oil until the container (or the syringe) is almost, but not completely full. Put the lid on firmly.

Fill in the engine data form and stick it on the bottle. Place the bottle in the mailing tub, post, and wait for the email with the results and conclusions.

Case study

Let’s Go has twin 4JH3 DTE Yanmar engines. When purchased, the surveyor carried out an oil analysis as part of the survey.

The exact age of the oil was unknown, but thought to be about two years and 15W-40. The engines had done 355 and 361 hours.

After 90 hours (a lot of it at cruising 3,000rpm) a repeat sample was taken from each engine by a surveyor.

The first samples were OK but when the second set arrived the port and starboard engines had some water (0.1%) in them, the oil had a low viscosity and, in the starboard engine, the copper content had increased three fold… which all sounds a bit worrying.

But in fact, there was an ‘innocent’ explanation for all of these issues.

The filled in paperwork for Let’s Go oil analysis. Credit: Gilbert Park

The samples had been taken with the engine running to warm it up for 20 minutes at 1,500rpm; the boat was in the dock, so the engine was not under load, and the boat hadn’t been used for a few weeks.

The water in the oil was probably condensation, the low oil viscosity was excess fuel by-passing the pistons, and copper from copper passivation.

Copper can come from wear, but what is more common is that the additives in oils can cause copper to leach from the heat exchanger tubes.

This occurs in ‘new’ engines (less than 1,500 hours) especially when they are run hot.

The levels found in the starboard engine were the same as the average found in a review of 30,000 samples from truck diesel engines.

What these results show is the value of repeated sampling and the need for expert interpretation, a bit like blood samples in humans!

Action to be taken in this case? None, repeat in 100 hours, just like the blood sample.

Just imagine what this would have done to the value of the boat if a single isolated result had been found by a surveyor.

Enjoy reading Why an oil test is vital for boat engine health?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price.

Print and digital editions are available through Magazines Direct – where you can also find the latest deals.

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

-

-

-

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

-

-

Follow us on Facebook, Instagram, TikTok and Twitter